Mobile crushing and screening plants are among the most innovative technologies providing revolutionary solutions in the construction and mining sectors. In this context, the mobile jaw and impact crushers manufactured by CONSTMACH are among our most preferred products for stone crushing and screening operations.

The superior performance, durability, and flexible design of our mobile crushing plants ensure that you stay a step ahead of the competition. The high efficiency and quality offered by our products help enhance your business's productivity while reducing costs. With CONSTMACH mobile jaw and impact crushers, tackling even the most challenging projects becomes easier and more profitable than ever.

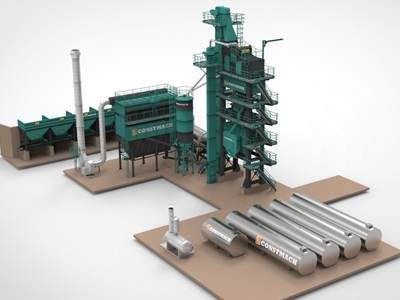

Product Features and Advantages

CONSTMACH mobile jaw and impact crushers are capable of crushing various types of rocks and excel in breaking hard stones such as limestone and basalt. One of the key features of these crushers is the ease of breaking large and hard rocks with the primary jaw crusher. The secondary impact crusher offers the capability to produce perfect cubic-shaped end products ranging from 0-60 mm, according to the needs of our customers.

Model Options

Among CONSTMACH's mobile crushing plants, various models are available to meet different needs. The CJC-60, CJC-90, and CJC-110 are primary jaw crusher models featured in the JS-1, JS-2, and JS-3 models, respectively. These models also include secondary impact crushers, CSI-1212 and CSI-1215. Each model is equipped with essential components such as a feeding hopper, grizzly feeder, by-pass (soil) belt conveyor, feeding conveyor between the jaw and impact crushers, vibrating screen, return and stock conveyors, wheeled mobile chassis, dust removal, and control systems.

Flexible and Mobile Structure

Our mobile crushers can be equipped with a diesel-electric generator if needed. The JS-1, JS-2, and JS-3 models consist of a dual-trailer combination. The first trailer includes the feeding hopper, jaw crusher, and feeding and by-pass conveyors, while the second trailer contains the secondary impact crusher, vibrating screen, feeding, return, and final product stock conveyors. The dust removal system is available on both chassis.

Typically, all models come with three different stock conveyors. However, depending on customer needs, an additional screen and stock conveyor can be added to produce a fourth fraction. This provides flexibility and allows for increased production capacity.

Superior Performance and Efficiency

The key advantages of CONSTMACH mobile jaw and impact crushers are:

- The capacity to crush a wide range of rock types from soft to hard.

- High sand ratio due to the special rotor design of the secondary impact crushers.

- Excellent cubic shape of end products.

User-Friendly and Advanced Technology

With a high-tech automation system and tablet control, using CONSTMACH mobile jaw and impact crushers is extremely easy. Compliance with international traffic regulations ensures that they are highly practical for transportation. These mobile crushers enhance your production efficiency while minimizing operational costs.

CONSTMACH mobile jaw and impact crushers are high-performance and durable products that optimize your stone crushing and screening processes. Choose CONSTMACH mobile crushers to increase your business productivity, reduce costs, and achieve excellent results even in the most challenging projects. Discover our products and experience the difference for yourself!

EN

EN TR

TR EN

EN ES

ES FR

FR RU

RU RS

RS AR

AR