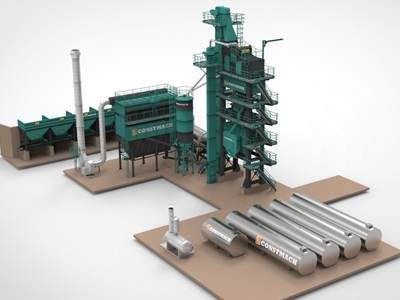

As CONSTMACH, Turkey's leading concrete batching plant manufacturer, we produce key concrete equipment such as stationary, mobile, compact, and on-site type concrete batching plants, concrete mixers, cement silos, and concrete block machines. We manufacture, transport, and install concrete mixing plants of various types and sizes, with capacities ranging from 15 to 300 m³/h. Over 300 CONSTMACH concrete batching plants are operational in more than 85 countries across six continents.

CONSTMACH concrete batching plants are classified into stationary (fixed), mobile (portable), and compact (skip) types. Our stationary plants offer the highest production capacity. Designed for long-term projects, stationary concrete batching plants provide the right solutions for specific sites. The capacities of our stationary concrete batching plants are classified as 60, 100, 120, 160, 200, and 240 m³/h. Depending on customer needs and capacity requirements, a single concrete batching plant can use two mixers simultaneously. You can see such applications in our DoubleMix 100 and DoubleMix 160 models.

The production capacity of our mobile concrete batching plants ranges from 30 to 120 m³/h. Mobile plants with capacities of 30, 60, and 100 m³/h are mounted on a single trailer. If needed, cement silos can be integrated into the chassis of the mobile plant. Our mobile concrete batching plants can be equipped with aggregate feeding systems that do not require the construction of loading ramps, thereby minimizing infrastructure costs.

High Technology and Control Systems

CONSTMACH concrete batching plants are equipped with high-tech control systems, featuring top-quality European-origin electronic components from SIEMENS and SCHNEIDER, as well as PLCs. The entire system is controlled through advanced software with sophisticated features and a user-friendly interface.

CONSTMACH concrete mixing plants are equipped with cement silos of various sizes, depending on the production capacity and application purpose. Cement silos with capacities ranging from 30 to 1000 tons are used in our plants. Silos up to 50 tons capacity are manufactured as split and welded, while those above 50 tons are preferred as split for ease of transport. CONSTMACH cement silos are equipped with dust filter systems, pressure relief (safety) valves, level indicators, butterfly valves, and air nozzles.

Concrete Batching Plants We Produce and Their Advantages

- Mobile Concrete Batching Plant

The mobile concrete batching plant is an innovative solution designed for concrete production in the construction industry, featuring a portable structure. These plants are typically mounted on a chassis and can be easily transported from one construction site to another. This portability provides a significant advantage in varying working conditions and different projects, making mobile plants indispensable, especially in remote or short-term projects.

Mobile concrete batching plants allow for fast and efficient concrete production even in remote locations where setting up a fixed plant is not practical. This is particularly critical in regions with limited transportation infrastructure. Additionally, the quick setup and easy dismantling features save time in projects and reduce overall costs.

Modern mobile concrete batching plants are equipped with high energy efficiency and automated control systems. These features reduce operational costs while minimizing the need for labor and increasing production efficiency. Moreover, they can produce up to 120 m³ of concrete per hour, providing sufficient production capacity for large-scale projects.

Fully automated control systems continuously maintain accurate concrete mix ratios, which is crucial for the durability and safety of structures. These systems enable the production of consistently high-quality concrete by minimizing errors. The features of mobile concrete batching plants make them suitable for a wide range of applications, from major infrastructure projects to rural development projects and post-disaster reconstruction efforts.

- Stationary Concrete Batching Plant

The stationary concrete batching plant is a concrete production facility typically chosen for large-scale and long-term construction projects, built on a permanent structure. These plants are permanently installed in a specific location and are usually designed to produce concrete in large capacities. Stationary concrete batching plants are ideal for large projects requiring high production capacity and continuous concrete supply.

Once installed, a stationary concrete batching plant does not need to be relocated, making it particularly suitable for infrastructure development, large-scale residential projects, and commercial facilities. These plants usually have the capacity to produce large quantities of concrete continuously, ensuring that the project progresses efficiently and on time.

Stationary concrete batching plants are also designed to optimize energy efficiency and material use. Modern stationary plants are equipped with automated control systems that accurately and consistently adjust concrete mix ratios. This ensures that concrete quality remains at a consistently high standard, which is critical for structural integrity.

The fixed nature of these plants also allows for the use of larger and heavier equipment, enhancing overall production efficiency. Stationary concrete batching plants can cover a large area and meet complex logistical needs, making them indispensable for urban development and large-scale industrial projects.

- Compact Concrete Batching Plant

The compact concrete batching plant is a concrete production facility designed for efficient use in confined spaces, offering an ideal solution for small to medium-sized projects. Due to its compact structure, this type of plant can be installed and operated even in limited spaces, making it suitable for urban projects or infrastructure development projects where space is restricted.

Compact concrete batching plants are noted for their portability and ease of installation. These features allow for quick setup and dismantling according to the project's needs. Additionally, these plants are generally more cost-effective compared to stationary plants, requiring less maintenance and being equipped with energy-efficient components.

Compact plants also have the capability to produce high-quality and consistent concrete. Modern automated control systems continuously adjust the concrete mix ratios correctly, supporting structural integrity and maximizing construction quality. These systems reduce labor costs while increasing the efficiency of the production process.

Preferred in small-scale and time-constrained projects, compact concrete batching plants can be effectively used in various applications, such as infrastructure improvements, road construction, and urban renewal projects. With the ability to adapt to narrow spaces, compact concrete batching plants enable high-performance concrete production even in constrained site conditions.

Your Solution Partner for Concrete Batching Plant Purchases

For professionals in the construction industry seeking excellence, we offer concrete batching plant solutions for sale from Constmach. Our plants, featuring innovative designs and advanced technology, are ideal for construction projects of all sizes. Manufactured in Turkey and proven in the global market, Constmach concrete batching plants are ready to provide you with high efficiency and durability.

At Constmach, we prioritize quality and performance in the construction industry with our concrete batching plant options for sale. Each of our concrete plants is designed to adapt to challenging working conditions and offers maximum efficiency with minimal maintenance requirements. Our customers can always feel secure with our extensive service network and technical support.

If your projects require high-quality concrete production, explore Constmach's concrete batching plant solutions for sale. Contact us to choose the most suitable model for your project and make a difference in your construction. With Constmach, ensure that your investment pays off and strengthen your leadership in the industry.

Concrete Batching Plant Prices Suitable for Every Business

Investing in a concrete batching plant is a crucial decision that directly impacts the efficiency and quality of your construction projects. Prices vary depending on the capacity, technology, and additional features of the chosen model. At Constmach, we ensure that you get the most value from your investment by offering solutions that fit every budget and meet the requirements of your project. Concrete batching plant prices should be evaluated based on the long-term benefits the machine will provide. By choosing a high-quality plant, you can gain advantages such as low maintenance costs and high production efficiency in the long run.

Constmach concrete batching plants are designed with durability and energy efficiency in mind, maximizing the value of your investment. Among our diverse model options are stationary, mobile, compact, and dry-type plants. Our prices are determined to be competitive and fair, reflecting industry standards.

Furthermore, with our plants produced to international standards and subjected to rigorous quality control processes, you are guaranteed to receive a high-standard product with every purchase. For more information on concrete batching plant prices and the most suitable solutions for your project, contact us. Constmach is ready to help you make a difference in your projects by offering high-quality solutions.

EN

EN TR

TR EN

EN ES

ES FR

FR RU

RU RS

RS AR

AR