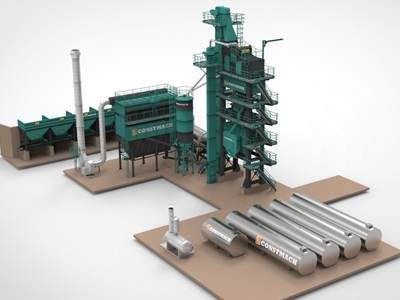

At CONSTMACH, we take pride in being a leading company in the production of compact concrete batching plants. With our innovative designs, high-tech solutions, and customer-oriented approach, we offer the best solutions to our customers seeking efficiency and reliability in concrete production. Our compact concrete batching plants stand out with their ability to deliver maximum performance even in limited spaces, along with easy portability and quick installation features.

Advantages of Compact Design

CONSTMACH Compact Concrete Batching Plants are specially designed models that can be transported in just one truck or a 40 ft. OT container and are preferred in situations where the installation site has very limited dimensions. Thanks to these features, they offer a wide range of usage possibilities, from urban projects to construction in rural areas. Compact concrete batching plants are also referred to as containerized concrete batching plants, and their production capacity ranges from 30 to 120 m³/h. This flexible capacity range provides a significant advantage in adapting to various types of projects.

Economic and Efficient Solutions

Our compact concrete batching plants offer economic benefits to users thanks to their easy-to-transport and quick-to-install design, requiring minimal infrastructure investment. For installation, a flat concrete surface capable of supporting the total load of the facility is sufficient. The fact that the cement silos have steel legs eliminates the need for customers to construct additional concrete foundations. Additionally, metal walls on both sides of the facility allow for the easy preparation of an aggregate feeding ramp. These features speed up the installation process, minimizing labor and time costs.

Technological Superiority

CONSTMACH compact concrete batching plants are designed and manufactured in accordance with CE standards. Our products are equipped with high-tech control and automation systems, including premium SIEMENS & SCHNEIDER brand electronic and electrical components and a PLC module. The facility is controlled by advanced software featuring sophisticated functionalities and a user-friendly interface. As a result, we offer our users full control and high efficiency in the concrete production process.

Mixer Types and Application Areas

Our compact concrete batching plants can be equipped with twin-shaft, single-shaft, pan, and planetary mixers, allowing for use in various applications such as ready-mix concrete, dry concrete, and precast concrete production. These diverse mixer options enable us to provide solutions suitable for different projects. The high performance of our mixers ensures the homogeneity and quality of the concrete mix while offering long-lasting use with low maintenance costs.

Innovative Transfer System

The transfer of aggregates from the aggregate hopper to the mixer using a bucket system instead of a belt conveyor is the key element that minimizes the dimensions of the application area. This innovative transfer system not only saves space but also enhances energy efficiency. Moreover, the dimensions of the aggregate hopper and other components are more compact compared to stationary batching plants. This compact structure allows our plant to be easily used in any field.

Galvanized Coating Options

Upon our customers' request, hot-dip galvanizing can be applied to all parts of our concrete batching plants. This coating increases the longevity of the plants and enhances their resistance to harsh environmental conditions. Galvanized coating provides superior protection against corrosion and minimizes the maintenance needs of your plant.

CONSTMACH compact concrete batching plants offer excellent solutions for concrete production with their high performance, easy portability, quick installation, and economic advantages. Manufactured in accordance with CE standards and equipped with high-tech control and automation systems, our plants provide a reliable and efficient production process for our customers. With a variety of mixer options and an innovative transfer system, our compact concrete batching plants offer solutions suitable for every project, backed by the assurance of CONSTMACH.

At CONSTMACH, we always prioritize customer satisfaction and work to provide the most suitable solutions for your needs. Contact us to learn more about our compact concrete batching plants and to determine the best solution for your projects.

EN

EN TR

TR EN

EN ES

ES FR

FR RU

RU RS

RS AR

AR