BS-30 is designed and developed to offer definite solutions to the most frequent problems in the concrete block making industry. BS-30 is always one step ahead between its rivals with its versatile concrete block producing capabilities. Multi-layer concrete block machines are incapable of producing various concrete blocks (curbstones, hollow blocks etc); but with its versatile single-layer structure, BS-30 is able to produce pavers, curbstones, hollow blocks etc. by installing appropriate molds on the machine. The fully scalable structure of the BS-30 plant ensures fulfilling its investors' requirements economically and rapidly, especially when investors demand more capacity.

With the PLC automation software which is developed by CONSTMACH R&D engineers, the whole BS-30 plant needs only one supervisor personnel to operate. The whole plant operates fully automatic so production quality for each cycle and production capacity for each working shift are maintained and stabilized. Automation system also makes it possible to operate the plant in various speeds. CONSTMACH engineers evaluated the traditional PLC control panel to a compact and simplified solution. This recently developed control panel benefits the latest improvements in PLC technology and offers a touch-screen LCD monitor with an easy to use graphical user interface. Automation system also provides an archiving and reporting tool.

Supervisors can access archived production data anytime; this data can also be printed out with a dot-matrix and/or inkjet printer connected to the system. Remote access capabilities are optionally provided with the automation system. Supervisors can access to the control system via any access point over LAN and/or internet. Any failure on the system can be diagnosed and firmware update can be performed through remote access connection.

MAIN VALUES OF THE MACHINE

| Production Capacity | 110 - 120 Pallet per hour |

|---|---|

| Pallet Size | 1.200 x 1.150 x 230 mm |

| Control | PLC Automation System (Schneider) |

| Hopper Capacity | 1.4 m³ |

| Hydraulic Oil Capacity | 400 lt |

| Upper Vibration | 3 kW x 2 |

| Lower Vibration | 4 kW x 4 |

| Total Electricty Capacity | 250 kW |

| Total Vibration Force | 30.000 |

| Maximum Product Height | 3.000 mm |

| Maximum Product Weight | 600 mm |

| Machine Chassis Frame | 10 mm |

| System of Vibration | Classic Belt and Pulley Vibration |

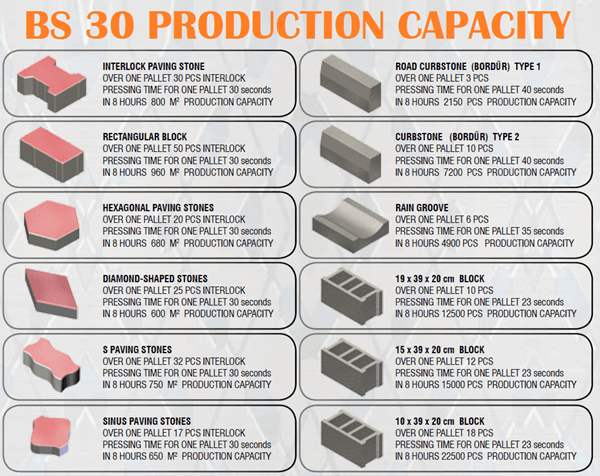

| Estimated Production Capacity in 8 Hours |

20 x 40 x 20 Block – 12.000 pieces Interlock – 28.000 pieces |

| Pressing Amount Per Press |

20 x 40 x 20 Block – 12 pieces Interlock – 30 pieces |

STACKING SYSTEM ROBOT

| Stacking Layer | 5 - 7 Row |

|---|---|

| Cleaning Brush | Present |

| Back Dry Product | Hydraulic Driver |

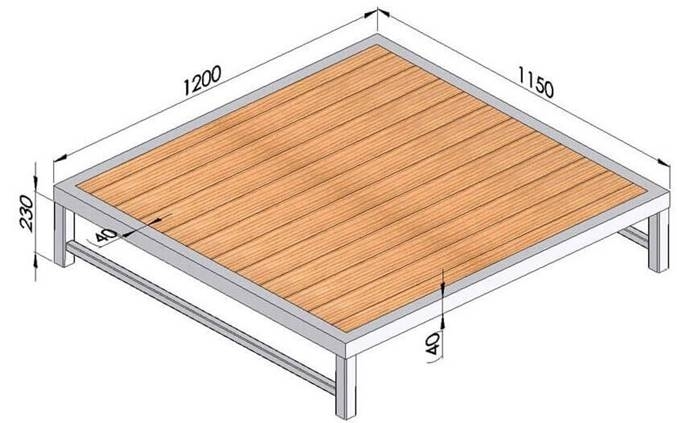

WOOD PALLET

| Pallet Size | 1.200 x 1.150 x 230 mm |

|---|---|

| Square Steel Thickness | 4 mm |

| Leg Thickness | 3.5 mm |

DRY PRODUCT CUBING ROBOT

| Pump Power | 7.5 kW, 40 lt/min |

|---|---|

| Profile Propulsion Power | 3 kW, 150 rpm |

| Rotational Power | 1.1 kW, 22 rpm |

| Chassis | 100 x 150 x 5 |

EN

EN TR

TR EN

EN ES

ES FR

FR RU

RU RS

RS AR

AR