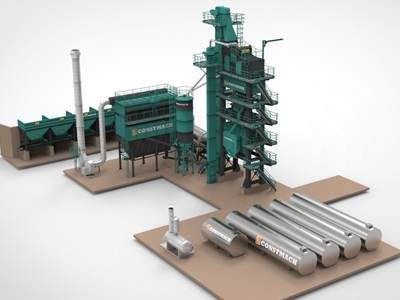

What is a Concrete Batching Plant? What are its Types and Where is it Used?

A concrete batching plant is a facility where ready-mix concrete, used in construction projects, is produced and distributed. These plants produce concrete by mixing aggregates such as sand, gravel, crushed stone, water, cement, and various chemical additives in specific proportions. The produced concrete is transported to construction sites via transit mixers or trucks. Concrete batching plants generally consist of components such as aggregate bins, aggregate weighing belts, mixer feed belts, main frame groups, cement silos, related equipment, and the automation system of the plant. These components ensure the efficient and effective execution of the concrete production process.

Types of Concrete Batching Plants

Concrete batching plants are designed in different types according to various needs and projects. Each plant type serves a specific purpose and should be chosen based on the requirements of the construction project. Below are the main types of concrete batching plants with detailed descriptions:

- Stationary Concrete Batching Plants

Stationary concrete batching plants are ideal for large and long-term projects. These plants are high-capacity facilities that require on-site installation. The main advantage of stationary plants is that they provide high efficiency and continuous production.

They are generally used in large infrastructure projects, dams, bridges, and highways where there is a long-term and high-volume concrete demand. Due to their robust infrastructure and various components, stationary plants are typically installed in larger areas and are more expensive. However, the efficiency and production capacity they provide in the long run offset this cost.

- Mobile Concrete Batching Plants

Mobile concrete batching plants stand out for their portability and quick installation. They are used in situations where the construction site changes or where there is a need for concrete in short-term projects. These plants can be transported by truck or trailer and can be set up and start production quickly. The biggest advantage of mobile batching plants is their flexibility and fast setup and commissioning. This is a significant advantage, especially for construction companies working in different locations. Additionally, mobile plants may be more cost-effective and occupy less space compared to stationary plants.

- Compact Concrete Batching Plants

Compact concrete batching plants combine the advantages of both mobile and stationary plants. They are generally ideal for medium-scale projects and provide high efficiency in limited spaces. Compact plants can be quickly set up and are portable due to their modular design. These plants can be easily used in both urban and rural projects. Their compact design allows for space savings while maintaining high production capacity. They are also notable for their low maintenance costs and energy efficiency.

- Temporary (Semi-Mobile) Concrete Batching Plants

Temporary concrete batching plants are facilities set up to meet the concrete needs of a project for a certain period. These plants can be relocated and reinstalled after the project is completed. Temporary plants can be quickly set up and commissioned like mobile plants, but they offer higher production capacity. Therefore, they are suitable for medium-sized and short-term large projects.

- Dry Type Concrete Batching Plants

Dry type concrete batching plants mix the concrete components in dry form, and water is added to the mix either in the transit mixer or at the construction site. In these plants, aggregates, cement, and other additives are mixed in dry form and loaded into mixer trucks. Water is added to this mixture in the mixer truck to complete the mixing process. Dry type plants are notable for their quick setup and low maintenance costs. They are suitable for small to medium-sized projects and allow the concrete to be mixed fresh on-site, helping maintain its quality during long-distance transport.

Each type of concrete batching plant is designed specifically according to the needs and requirements of different projects. Choosing the right plant is crucial for the efficiency and success of the project. Therefore, selecting the most suitable concrete batching plant by considering the project’s requirements is of great importance.

Applications of Concrete Batching Plants

Concrete batching plants are widely used in various construction projects. These facilities are indispensable in any type of structure and infrastructure project where concrete is needed. Below are the main application areas of concrete batching plants:

- Infrastructure Projects

Infrastructure projects are one of the areas where concrete batching plants are used most intensively. Large-scale projects such as bridges, highways, tunnels, railway viaducts, and dams require a high amount of high-quality concrete. Stationary concrete plants offer an ideal solution to meet the continuous and high-capacity concrete demand of such projects. Additionally, since these projects are typically long-term, the efficiency and durability of stationary plants provide a significant advantage.

- Commercial and Industrial Buildings

Commercial and industrial buildings are another area where large volumes of concrete are needed. Concrete batching plants are used in the construction of large structures such as shopping malls, factories, warehouses, office buildings, and hotels. Mobile and stationary concrete plants are preferred for these projects to ensure rapid progress and high-quality concrete. Compact batching plants offer an effective solution in urban projects by overcoming space constraints.

- Residential Construction

Residential construction is another area where concrete batching plants are widely used. Projects such as apartment buildings, villas, residential complexes, and mass housing require a consistent supply of concrete. Dry type concrete plants offer a flexible and economical solution for such projects. In residential construction, the quality and durability of the concrete ensure that the buildings are long-lasting and safe.

- Agricultural and Rural Projects

Agricultural and rural area projects also fall within the application range of concrete batching plants. Projects such as irrigation canals, water storage tanks, animal shelters, and rural roads commonly use concrete. Mobile batching plants stand out in these projects for their portability and quick setup advantages. Positioning the concrete plants close to the site in rural areas reduces logistics costs and accelerates the completion of projects.

- Prefabricated Building Element Production

Concrete batching plants are also used in the production of prefabricated building elements. Prefabricated panels, beams, columns, and flooring elements are produced in advance and transported to the construction site for assembly. In this process, the homogeneous and high-quality concrete provided by batching plants is crucial for the durability and performance of the prefabricated elements. Pre-feed concrete plants ensure a fast and continuous flow of concrete in such production processes.

- Special Projects

Special projects typically have unique and specific concrete requirements. Projects such as sports facilities, airports, ports, power plants, and water treatment plants require special concrete mixtures and properties. Concrete batching plants can be customized according to the needs of these projects and ensure the continuous supply of the desired concrete mixture. Temporary concrete plants offer an efficient solution in these projects by providing quick installation and flexibility.

Concrete batching plants are indispensable elements of the construction industry and have a wide range of applications in various projects. By selecting the correct type of concrete batching plant based on the specific needs of each project, the most efficient and economical solution can be achieved.

EN

EN TR

TR EN

EN ES

ES FR

FR RU

RU RS

RS AR

AR