Concrete, the cornerstone of the construction industry, is one of the indispensable building materials of the modern world. The key to constructing strong, durable, and reliable structures lies in producing high-quality concrete. At Constmach, we meet this need by offering our highest quality stationary concrete batching plants. With our SStationary-30, Stationary-60, Stationary-100, Stationary-120, Stationary-160, and Stationary-240 models, we are by your side in all your construction projects.

Constmach is a leading company in the industry with years of experience in concrete batching plant production. Our mission is to provide our customers with the highest quality, most reliable, and durable concrete batching plants. With our principles of innovation, quality, and customer satisfaction, we continuously develop our products by closely following technological advancements.

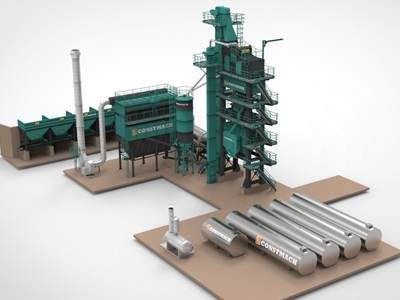

Features and Advantages of Our Stationary Concrete Batching Plants

- Stationary-30

Our Stationary-30 model is an ideal solution for small and medium-sized projects. With a daily production capacity of 30 m³, it stands out with its compact structure and high efficiency. It is a preferred model due to its easy installation and low operating costs. - Stationary-60

Stationary-60 is an excellent choice for medium-sized projects. With a daily production capacity of 60 m³, this model provides time and cost savings in your projects with its high mixing performance and fast production cycle. - Stationary-100

Stationary-100 is ideal for large-scale projects. With a daily production capacity of 100 m³, it offers high efficiency. Thanks to its advanced automation systems, it provides a user-friendly experience and allows for error-free production. - Stationary-120

With a daily production capacity of 120 m³, our Stationary-120 model is designed for large and complex projects. It ensures excellent concrete quality with its high-quality components and powerful mixing mechanism. - Stationary-160

Stationary-160, with a daily production capacity of 160 m³, is a perfect choice for mega projects. It ensures maximum efficiency in the production process with its high-performance mixing system and advanced automation features. - Stationary-240

Our largest model, Stationary-240, has a daily production capacity of 240 m³. It provides uninterrupted and high-quality production even in the most demanding projects. With its high durability and robust structure, it delivers superior performance even in challenging conditions.

Advanced Technology and Innovation

Constmach stationary concrete batching plants are equipped with high-tech control systems. They deliver top-level performance with European-manufactured electronic components and PLC modules from Siemens and Schneider. All plant units are controlled by advanced software with a user-friendly interface. A manual control panel is also available for emergencies.

Cement Silos

Constmach stationary concrete batching plants are equipped with cement silos of different sizes, depending on the production capacity and application purpose. Cement silos with capacities ranging from 30 to 1,000 tons can be used. Silos up to 50 tons are produced in bolted and welded types, while those with capacities above 50 tons are preferred in bolted types for easy transportation. All our cement silos are equipped with dust filters, pressure relief (safety) valves, level indicators, butterfly valves, and air nozzles.

Adaptation to Climate Conditions

Our company is well aware of the impact of climate conditions on concrete quality. In cold climate regions (Russia, Kazakhstan, Ukraine, Northern Europe, etc.), our stationary concrete batching plants are heated with steam generators and insulated panels, while in hot climate regions (Middle East, Gulf countries, or Africa), the concrete water is cooled with chillers.

Aggregate Pre-Feeding Systems

Our aggregate pre-feeding systems offer alternative solutions that can replace the loading ramps required to load materials into the bunkers with loaders. When aggregate pre-feeding systems are used, the need for a loading ramp is eliminated.

Different Layout Plans

Depending on the conditions of the area where our stationary concrete batching plants will be installed, different layout plans and site arrangements are applied. This flexibility allows us to provide solutions that fully meet the needs of your projects.

At Constmach, we prioritize quality, reliability, and customer satisfaction in the production of stationary concrete batching plants. With our Stationary-30, Stationary-60, Stationary-100, Stationary-120, Stationary-160, and Stationary-240 models, we offer solutions suitable for all types of construction projects. We make a difference in our industry with our innovative approach and advanced technology, aiming to provide our customers with the best service.

EN

EN TR

TR EN

EN ES

ES FR

FR RU

RU RS

RS AR

AR